Unlocking Efficiency: UL FM Gate Valve Solutions for Enhanced Fire Safety and Flow Control

2025-12-22

In the demanding world of industrial and commercial facilities, ensuring robust fire safety and precise flow control is paramount. When every second counts and reliability cannot be compromised, engineers and safety managers turn to cutting-edge solutions. Enter UL FM gate valves—engineered to enhance both fire protection and operational efficiency. At DRIFCO, we understand that superior valve technology isn't just about meeting standards; it's about exceeding expectations in real-world applications. In this blog, we delve into how these advanced valves unlock efficiency, safeguard assets, and streamline processes, offering insights that could revolutionize your approach to fire safety and flow management. Stay tuned to explore the transformative potential of UL FM gate valve solutions.

UL FM Gate Valve Innovations for Fire Safety

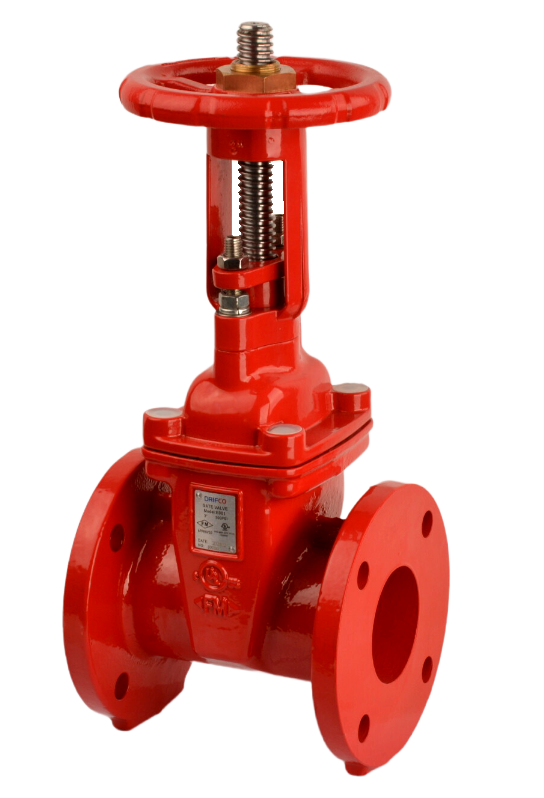

When it comes to fire safety, every component matters, and gate valves are no exception. UL FM gate valves represent a leap forward in this critical area. These valves incorporate advanced materials and precision engineering to ensure reliable shut-off capabilities during fire emergencies, preventing the spread of fire and protecting both life and property.

Innovations in UL FM gate valves include features like enhanced sealing mechanisms that maintain integrity under extreme heat and pressure. For example, some models now utilize heat-resistant alloys and self-locking designs to reduce the risk of failure when exposed to high temperatures. This not only meets stringent safety standards but also offers peace of mind for facility managers and engineers.

Beyond basic functionality, these valves are designed with user-friendly features such as easy operation and maintenance access, making them practical for a wide range of applications. By integrating cutting-edge technology, UL FM gate valves set a new benchmark in fire safety equipment, ensuring that systems remain effective in the most challenging conditions.

Improving Flow Control with Advanced Valve Solutions

When it comes to fire safety, every component matters, and gate valves are no exception. UL FM gate valves represent a leap forward in this critical area. These valves incorporate advanced materials and precision engineering to ensure reliable shut-off capabilities during fire emergencies, preventing the spread of fire and protecting both life and property.

Innovations in UL FM gate valves include features like enhanced sealing mechanisms that maintain integrity under extreme heat and pressure. For example, some models now utilize heat-resistant alloys and self-locking designs to reduce the risk of failure when exposed to high temperatures. This not only meets stringent safety standards but also offers peace of mind for facility managers and engineers.

Beyond basic functionality, these valves are designed with user-friendly features such as easy operation and maintenance access, making them practical for a wide range of applications. By integrating cutting-edge technology, UL FM gate valves set a new benchmark in fire safety equipment, ensuring that systems remain effective in the most challenging conditions.

When it comes to optimizing industrial processes, advanced valve solutions are game-changers, offering precise control over fluid and gas flow that traditional valves simply can't match. These innovations integrate smart technologies like sensors and actuators, enabling real-time adjustments to pressure and flow rates, which boosts efficiency and reduces waste. In sectors like oil and gas or water treatment, this means smoother operations and fewer unexpected shutdowns, helping plants run like well-oiled machines without the usual hiccups.

Beyond basic functionality, advanced valves bring a level of adaptability that's essential for modern applications. Think about systems that handle varying temperatures or corrosive materials—these valves are designed to withstand harsh conditions while maintaining accuracy. Features like automated feedback loops and predictive maintenance capabilities mean they not only respond instantly to changes but also alert operators before issues escalate, cutting down on costly repairs and keeping safety at the forefront of every operation.

What sets these solutions apart is their integration with broader control systems, creating a seamless network that enhances overall performance. By leveraging data analytics and connectivity, advanced valves help shift from reactive to proactive management, allowing teams to make informed decisions based on live insights. This holistic approach ensures that flow control isn't just a standalone task but a key part of driving sustainability and productivity across entire facilities, making them smarter and more resilient in the long run.

How UL FM Certification Enhances Fire Protection Efficiency

When it comes to fire safety, every component matters, and gate valves are no exception. UL FM gate valves represent a leap forward in this critical area. These valves incorporate advanced materials and precision engineering to ensure reliable shut-off capabilities during fire emergencies, preventing the spread of fire and protecting both life and property.

Innovations in UL FM gate valves include features like enhanced sealing mechanisms that maintain integrity under extreme heat and pressure. For example, some models now utilize heat-resistant alloys and self-locking designs to reduce the risk of failure when exposed to high temperatures. This not only meets stringent safety standards but also offers peace of mind for facility managers and engineers.

Beyond basic functionality, these valves are designed with user-friendly features such as easy operation and maintenance access, making them practical for a wide range of applications. By integrating cutting-edge technology, UL FM gate valves set a new benchmark in fire safety equipment, ensuring that systems remain effective in the most challenging conditions.

When it comes to optimizing industrial processes, advanced valve solutions are game-changers, offering precise control over fluid and gas flow that traditional valves simply can't match. These innovations integrate smart technologies like sensors and actuators, enabling real-time adjustments to pressure and flow rates, which boosts efficiency and reduces waste. In sectors like oil and gas or water treatment, this means smoother operations and fewer unexpected shutdowns, helping plants run like well-oiled machines without the usual hiccups.

Beyond basic functionality, advanced valves bring a level of adaptability that's essential for modern applications. Think about systems that handle varying temperatures or corrosive materials—these valves are designed to withstand harsh conditions while maintaining accuracy. Features like automated feedback loops and predictive maintenance capabilities mean they not only respond instantly to changes but also alert operators before issues escalate, cutting down on costly repairs and keeping safety at the forefront of every operation.

What sets these solutions apart is their integration with broader control systems, creating a seamless network that enhances overall performance. By leveraging data analytics and connectivity, advanced valves help shift from reactive to proactive management, allowing teams to make informed decisions based on live insights. This holistic approach ensures that flow control isn't just a standalone task but a key part of driving sustainability and productivity across entire facilities, making them smarter and more resilient in the long run.

UL FM Certification sets a rigorous benchmark for fire safety systems, ensuring products undergo extensive testing under realistic conditions. This not only verifies their performance but also boosts user confidence, leading to more effective implementation and maintenance. By identifying and addressing potential weaknesses early, certified equipment reduces the risk of failures during emergencies, thereby optimizing overall fire protection efficiency.

In addition to technical validation, this certification process fosters innovation among manufacturers, pushing them to develop advanced solutions that exceed standard requirements. It encourages a proactive approach to safety, where continuous improvements and updates are prioritized. As a result, buildings and facilities equipped with UL FM certified systems often demonstrate enhanced resilience and faster response times in fire incidents.

Ultimately, UL FM Certification streamlines regulatory compliance and insurance assessments, reducing bureaucratic hurdles and operational delays. By providing clear, trusted guidelines, it helps organizations make informed decisions about their fire protection strategies. This holistic enhancement not only safeguards assets but also supports sustainable safety practices in diverse industries.

Gate Valve Applications in Industrial Safety Systems

When it comes to fire safety, every component matters, and gate valves are no exception. UL FM gate valves represent a leap forward in this critical area. These valves incorporate advanced materials and precision engineering to ensure reliable shut-off capabilities during fire emergencies, preventing the spread of fire and protecting both life and property.

Innovations in UL FM gate valves include features like enhanced sealing mechanisms that maintain integrity under extreme heat and pressure. For example, some models now utilize heat-resistant alloys and self-locking designs to reduce the risk of failure when exposed to high temperatures. This not only meets stringent safety standards but also offers peace of mind for facility managers and engineers.

Beyond basic functionality, these valves are designed with user-friendly features such as easy operation and maintenance access, making them practical for a wide range of applications. By integrating cutting-edge technology, UL FM gate valves set a new benchmark in fire safety equipment, ensuring that systems remain effective in the most challenging conditions.

When it comes to optimizing industrial processes, advanced valve solutions are game-changers, offering precise control over fluid and gas flow that traditional valves simply can't match. These innovations integrate smart technologies like sensors and actuators, enabling real-time adjustments to pressure and flow rates, which boosts efficiency and reduces waste. In sectors like oil and gas or water treatment, this means smoother operations and fewer unexpected shutdowns, helping plants run like well-oiled machines without the usual hiccups.

Beyond basic functionality, advanced valves bring a level of adaptability that's essential for modern applications. Think about systems that handle varying temperatures or corrosive materials—these valves are designed to withstand harsh conditions while maintaining accuracy. Features like automated feedback loops and predictive maintenance capabilities mean they not only respond instantly to changes but also alert operators before issues escalate, cutting down on costly repairs and keeping safety at the forefront of every operation.

What sets these solutions apart is their integration with broader control systems, creating a seamless network that enhances overall performance. By leveraging data analytics and connectivity, advanced valves help shift from reactive to proactive management, allowing teams to make informed decisions based on live insights. This holistic approach ensures that flow control isn't just a standalone task but a key part of driving sustainability and productivity across entire facilities, making them smarter and more resilient in the long run.

UL FM Certification sets a rigorous benchmark for fire safety systems, ensuring products undergo extensive testing under realistic conditions. This not only verifies their performance but also boosts user confidence, leading to more effective implementation and maintenance. By identifying and addressing potential weaknesses early, certified equipment reduces the risk of failures during emergencies, thereby optimizing overall fire protection efficiency.

In addition to technical validation, this certification process fosters innovation among manufacturers, pushing them to develop advanced solutions that exceed standard requirements. It encourages a proactive approach to safety, where continuous improvements and updates are prioritized. As a result, buildings and facilities equipped with UL FM certified systems often demonstrate enhanced resilience and faster response times in fire incidents.

Ultimately, UL FM Certification streamlines regulatory compliance and insurance assessments, reducing bureaucratic hurdles and operational delays. By providing clear, trusted guidelines, it helps organizations make informed decisions about their fire protection strategies. This holistic enhancement not only safeguards assets but also supports sustainable safety practices in diverse industries.

Gate valves are widely used in industrial safety systems, thanks to their robust design and reliable sealing capabilities. They are typically installed in pipelines where flow needs to be completely shut off to prevent accidents or control hazardous materials, such as in chemical plants, oil refineries, and power generation facilities. For example, in an emergency shutdown scenario, a gate valve can quickly isolate a section of piping from the rest of the system, minimizing the risk of leaks or explosions, ensuring the safety of personnel and the environment.

Beyond basic isolation, gate valves play a critical role in safety relief systems by providing a fail-safe mechanism. In high-pressure applications, they are often used as block valves to protect equipment like pressure vessels or boilers from overpressure conditions. Their full-bore design allows for minimal flow restriction when open, which is essential for maintaining system efficiency, while their tight seal when closed helps contain dangerous substances, making them a preferred choice in industries where operational safety is paramount.

Compared to other valve types, gate valves offer distinct advantages in safety contexts due to their simple operation and durability under extreme conditions. They are commonly employed in fire protection systems, where they must remain functional during emergencies to control water or foam flow. Additionally, their adaptability to various materials and sizes makes them versatile for custom safety configurations, ensuring compliance with stringent industrial regulations and enhancing overall system resilience against potential failures.

Maintenance Tips for Optimizing Valve Performance

When it comes to fire safety, every component matters, and gate valves are no exception. UL FM gate valves represent a leap forward in this critical area. These valves incorporate advanced materials and precision engineering to ensure reliable shut-off capabilities during fire emergencies, preventing the spread of fire and protecting both life and property.

Innovations in UL FM gate valves include features like enhanced sealing mechanisms that maintain integrity under extreme heat and pressure. For example, some models now utilize heat-resistant alloys and self-locking designs to reduce the risk of failure when exposed to high temperatures. This not only meets stringent safety standards but also offers peace of mind for facility managers and engineers.

Beyond basic functionality, these valves are designed with user-friendly features such as easy operation and maintenance access, making them practical for a wide range of applications. By integrating cutting-edge technology, UL FM gate valves set a new benchmark in fire safety equipment, ensuring that systems remain effective in the most challenging conditions.

When it comes to optimizing industrial processes, advanced valve solutions are game-changers, offering precise control over fluid and gas flow that traditional valves simply can't match. These innovations integrate smart technologies like sensors and actuators, enabling real-time adjustments to pressure and flow rates, which boosts efficiency and reduces waste. In sectors like oil and gas or water treatment, this means smoother operations and fewer unexpected shutdowns, helping plants run like well-oiled machines without the usual hiccups.

Beyond basic functionality, advanced valves bring a level of adaptability that's essential for modern applications. Think about systems that handle varying temperatures or corrosive materials—these valves are designed to withstand harsh conditions while maintaining accuracy. Features like automated feedback loops and predictive maintenance capabilities mean they not only respond instantly to changes but also alert operators before issues escalate, cutting down on costly repairs and keeping safety at the forefront of every operation.

What sets these solutions apart is their integration with broader control systems, creating a seamless network that enhances overall performance. By leveraging data analytics and connectivity, advanced valves help shift from reactive to proactive management, allowing teams to make informed decisions based on live insights. This holistic approach ensures that flow control isn't just a standalone task but a key part of driving sustainability and productivity across entire facilities, making them smarter and more resilient in the long run.

UL FM Certification sets a rigorous benchmark for fire safety systems, ensuring products undergo extensive testing under realistic conditions. This not only verifies their performance but also boosts user confidence, leading to more effective implementation and maintenance. By identifying and addressing potential weaknesses early, certified equipment reduces the risk of failures during emergencies, thereby optimizing overall fire protection efficiency.

In addition to technical validation, this certification process fosters innovation among manufacturers, pushing them to develop advanced solutions that exceed standard requirements. It encourages a proactive approach to safety, where continuous improvements and updates are prioritized. As a result, buildings and facilities equipped with UL FM certified systems often demonstrate enhanced resilience and faster response times in fire incidents.

Ultimately, UL FM Certification streamlines regulatory compliance and insurance assessments, reducing bureaucratic hurdles and operational delays. By providing clear, trusted guidelines, it helps organizations make informed decisions about their fire protection strategies. This holistic enhancement not only safeguards assets but also supports sustainable safety practices in diverse industries.

Gate valves are widely used in industrial safety systems, thanks to their robust design and reliable sealing capabilities. They are typically installed in pipelines where flow needs to be completely shut off to prevent accidents or control hazardous materials, such as in chemical plants, oil refineries, and power generation facilities. For example, in an emergency shutdown scenario, a gate valve can quickly isolate a section of piping from the rest of the system, minimizing the risk of leaks or explosions, ensuring the safety of personnel and the environment.

Beyond basic isolation, gate valves play a critical role in safety relief systems by providing a fail-safe mechanism. In high-pressure applications, they are often used as block valves to protect equipment like pressure vessels or boilers from overpressure conditions. Their full-bore design allows for minimal flow restriction when open, which is essential for maintaining system efficiency, while their tight seal when closed helps contain dangerous substances, making them a preferred choice in industries where operational safety is paramount.

Compared to other valve types, gate valves offer distinct advantages in safety contexts due to their simple operation and durability under extreme conditions. They are commonly employed in fire protection systems, where they must remain functional during emergencies to control water or foam flow. Additionally, their adaptability to various materials and sizes makes them versatile for custom safety configurations, ensuring compliance with stringent industrial regulations and enhancing overall system resilience against potential failures.

Keeping your valves in top condition can dramatically reduce downtime and improve system reliability. Proper maintenance isn't just about fixing problems as they arise—it's about creating a proactive routine that prevents issues before they start. With regular checks, you can catch minor wear early and address it before it leads to a costly failure, ensuring your operations run smoothly and efficiently.

Effective valve maintenance involves more than just occasional inspections; it's about integrating specific strategies like thermal cycling or using advanced sealants to adapt to different environments. For instance, in high-temperature applications, applying a suitable lubricant can prevent sticking and corrosion, which often goes unnoticed until it's too late. This kind of targeted approach not only extends the valve's lifespan but also optimizes its performance, making your equipment more resilient and reducing long-term costs.

Don't overlook the importance of documentation and training. Keeping detailed records of each valve's history helps track patterns and plan future maintenance, while training your team on the latest techniques ensures consistent care. By staying ahead with these practices, you'll not only meet but exceed performance expectations, giving your system a clear edge in reliability and efficiency over others that rely on reactive measures only.

Future Trends in Fire Safety and Flow Management

When it comes to fire safety, every component matters, and gate valves are no exception. UL FM gate valves represent a leap forward in this critical area. These valves incorporate advanced materials and precision engineering to ensure reliable shut-off capabilities during fire emergencies, preventing the spread of fire and protecting both life and property.

Innovations in UL FM gate valves include features like enhanced sealing mechanisms that maintain integrity under extreme heat and pressure. For example, some models now utilize heat-resistant alloys and self-locking designs to reduce the risk of failure when exposed to high temperatures. This not only meets stringent safety standards but also offers peace of mind for facility managers and engineers.

Beyond basic functionality, these valves are designed with user-friendly features such as easy operation and maintenance access, making them practical for a wide range of applications. By integrating cutting-edge technology, UL FM gate valves set a new benchmark in fire safety equipment, ensuring that systems remain effective in the most challenging conditions.

When it comes to optimizing industrial processes, advanced valve solutions are game-changers, offering precise control over fluid and gas flow that traditional valves simply can't match. These innovations integrate smart technologies like sensors and actuators, enabling real-time adjustments to pressure and flow rates, which boosts efficiency and reduces waste. In sectors like oil and gas or water treatment, this means smoother operations and fewer unexpected shutdowns, helping plants run like well-oiled machines without the usual hiccups.

Beyond basic functionality, advanced valves bring a level of adaptability that's essential for modern applications. Think about systems that handle varying temperatures or corrosive materials—these valves are designed to withstand harsh conditions while maintaining accuracy. Features like automated feedback loops and predictive maintenance capabilities mean they not only respond instantly to changes but also alert operators before issues escalate, cutting down on costly repairs and keeping safety at the forefront of every operation.

What sets these solutions apart is their integration with broader control systems, creating a seamless network that enhances overall performance. By leveraging data analytics and connectivity, advanced valves help shift from reactive to proactive management, allowing teams to make informed decisions based on live insights. This holistic approach ensures that flow control isn't just a standalone task but a key part of driving sustainability and productivity across entire facilities, making them smarter and more resilient in the long run.

UL FM Certification sets a rigorous benchmark for fire safety systems, ensuring products undergo extensive testing under realistic conditions. This not only verifies their performance but also boosts user confidence, leading to more effective implementation and maintenance. By identifying and addressing potential weaknesses early, certified equipment reduces the risk of failures during emergencies, thereby optimizing overall fire protection efficiency.

In addition to technical validation, this certification process fosters innovation among manufacturers, pushing them to develop advanced solutions that exceed standard requirements. It encourages a proactive approach to safety, where continuous improvements and updates are prioritized. As a result, buildings and facilities equipped with UL FM certified systems often demonstrate enhanced resilience and faster response times in fire incidents.

Ultimately, UL FM Certification streamlines regulatory compliance and insurance assessments, reducing bureaucratic hurdles and operational delays. By providing clear, trusted guidelines, it helps organizations make informed decisions about their fire protection strategies. This holistic enhancement not only safeguards assets but also supports sustainable safety practices in diverse industries.

Gate valves are widely used in industrial safety systems, thanks to their robust design and reliable sealing capabilities. They are typically installed in pipelines where flow needs to be completely shut off to prevent accidents or control hazardous materials, such as in chemical plants, oil refineries, and power generation facilities. For example, in an emergency shutdown scenario, a gate valve can quickly isolate a section of piping from the rest of the system, minimizing the risk of leaks or explosions, ensuring the safety of personnel and the environment.

Beyond basic isolation, gate valves play a critical role in safety relief systems by providing a fail-safe mechanism. In high-pressure applications, they are often used as block valves to protect equipment like pressure vessels or boilers from overpressure conditions. Their full-bore design allows for minimal flow restriction when open, which is essential for maintaining system efficiency, while their tight seal when closed helps contain dangerous substances, making them a preferred choice in industries where operational safety is paramount.

Compared to other valve types, gate valves offer distinct advantages in safety contexts due to their simple operation and durability under extreme conditions. They are commonly employed in fire protection systems, where they must remain functional during emergencies to control water or foam flow. Additionally, their adaptability to various materials and sizes makes them versatile for custom safety configurations, ensuring compliance with stringent industrial regulations and enhancing overall system resilience against potential failures.

Keeping your valves in top condition can dramatically reduce downtime and improve system reliability. Proper maintenance isn't just about fixing problems as they arise—it's about creating a proactive routine that prevents issues before they start. With regular checks, you can catch minor wear early and address it before it leads to a costly failure, ensuring your operations run smoothly and efficiently.

Effective valve maintenance involves more than just occasional inspections; it's about integrating specific strategies like thermal cycling or using advanced sealants to adapt to different environments. For instance, in high-temperature applications, applying a suitable lubricant can prevent sticking and corrosion, which often goes unnoticed until it's too late. This kind of targeted approach not only extends the valve's lifespan but also optimizes its performance, making your equipment more resilient and reducing long-term costs.

Don't overlook the importance of documentation and training. Keeping detailed records of each valve's history helps track patterns and plan future maintenance, while training your team on the latest techniques ensures consistent care. By staying ahead with these practices, you'll not only meet but exceed performance expectations, giving your system a clear edge in reliability and efficiency over others that rely on reactive measures only.

Looking ahead, fire safety and flow management are evolving rapidly, driven by technological breakthroughs and growing environmental concerns. One key trend is the integration of IoT sensors and AI algorithms into building systems, enabling real-time monitoring of heat, smoke, and crowd movements. This smart approach not only enhances early detection but also optimizes evacuation routes dynamically, reducing panic and bottlenecks in emergencies. For instance, some modern buildings now feature automated ventilation controls that adjust airflow based on fire location, helping contain flames while maintaining safe escape paths.

Another emerging aspect is the shift toward sustainable materials and designs that improve fire resistance without heavy reliance on harmful chemicals. Advances in flame-retardant composites and non-toxic coatings are making structures safer and greener. This trend aligns with global efforts to mitigate climate change, as it reduces the environmental impact of fire suppression methods. Additionally, urban planning is increasingly incorporating fire-safe zoning and green spaces to enhance natural ventilation, which can slow fire spread in densely populated areas, offering a dual benefit for safety and urban livability.

Furthermore, personalized safety protocols and community-based initiatives are gaining traction, moving beyond one-size-fits-all solutions. Technologies like mobile apps provide tailored evacuation guidance based on individual locations, while public education campaigns foster proactive risk awareness. These human-centric strategies complement technical innovations, creating resilient systems that adapt to diverse scenarios—from high-rise fires to wildfire-prone regions. Ultimately, the future of fire safety and flow management lies in blending cutting-edge tech with holistic, sustainable practices to build safer, more responsive environments for all.

FAQ

UL FM certified gate valves offer dual benefits: they ensure compliance with rigorous fire safety standards through UL listing and deliver reliable flow control verified by FM approval, which enhances system efficiency by reducing maintenance needs and operational disruptions.

These valves are engineered for precise flow regulation, featuring robust designs that minimize pressure drops and maintain consistent performance under emergency conditions, directly contributing to faster response times and more effective fire suppression.

Beyond meeting certification requirements, UL FM gate valves integrate advanced materials and sealing technologies that resist corrosion and wear, prolonging valve life and ensuring dependable operation during fire events, thus adding a layer of resilience to safety systems.

The combined UL and FM certifications provide unparalleled reliability, as they undergo strict testing for both fire safety and performance, coupled with often innovative designs like low-torque operation or compact footprints that save space and installation costs.

In industrial facilities with complex piping networks, these valves streamline maintenance by allowing easier access and quicker inspections without full system shutdowns, leading to reduced downtime and lower long-term operational expenses.

Regular visual checks for leaks, lubrication of moving parts per manufacturer guidelines, and periodic functional tests are key, with the certifications ensuring that maintenance protocols are tailored to sustain both safety and flow control integrity over time.

Conclusion

UL FM Gate Valve solutions represent a significant leap in fire safety and flow control, integrating innovations highlighted in sections such as UL FM Gate Valve Innovations for Fire Safety and Improving Flow Control with Advanced Valve Solutions. These valves are engineered to provide robust protection in critical scenarios, leveraging advanced materials and designs that enhance performance while ensuring reliability. The integration of UL FM Certification, as discussed in How UL FM Certification Enhances Fire Protection Efficiency, adds a layer of trust by verifying that these products meet stringent safety standards, contributing to overall system efficiency. Applications span across industrial settings detailed in Gate Valve Applications in Industrial Safety Systems, where precise flow management is essential for preventing accidents and maintaining operational continuity.

To sustain optimal performance, Maintenance Tips for Optimizing Valve Performance emphasize regular inspections and proactive upkeep, which are crucial for longevity and safety. Looking ahead, Future Trends in Fire Safety and Flow Management suggest ongoing advancements in smart technology and automation, promising even greater efficiency and integration in safety systems. This holistic approach not only unlocks operational efficiency but also reinforces the critical role of gate valves in safeguarding lives and assets, making them indispensable components in modern safety infrastructures.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com