Benefits of HDPE Microduct Straight Optic Connectors

2024-05-22

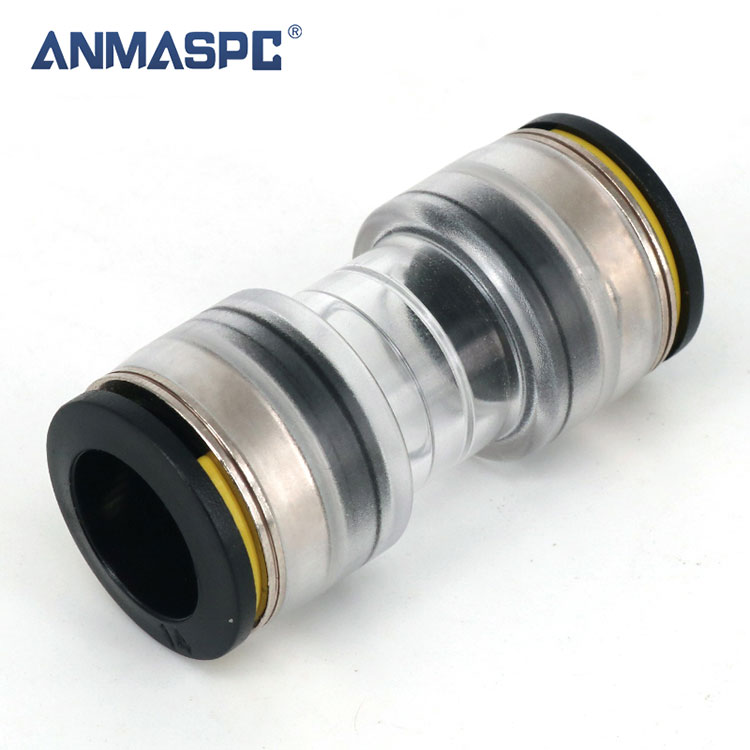

An HDPE microduct straight optic connector is a specialized fitting used in fiber optic cable installations. It is designed to join or extend microducts made of High-Density Polyethylene (HDPE) to ensure a secure and sealed pathway for fiber optic cables. Here's a detailed overview of its features, benefits, applications, and installation considerations:

Features

1. Material:

- Made from high-quality HDPE or other durable plastics to match the microduct material.

- Resistant to environmental factors such as UV radiation, moisture, and temperature fluctuations.

2. Design:

- Straight connectors provide a direct, in-line connection between two microducts.

- Usually features a push-fit or compression mechanism for easy installation and a secure fit.

3. Sealing:

- Equipped with O-rings or gaskets to ensure airtight and watertight seals, preventing the ingress of dirt and moisture.

4. Sizes:

- Available in various sizes to match different microduct diameters, commonly ranging from 5mm to 16mm.

5. Color Coding:

- Some connectors are color-coded for easy identification and to match specific microduct types or sizes.

Benefits

1. Easy Installation:

- Quick and straightforward to install, typically requiring no special tools.

- Push-fit or compression fittings allow for rapid deployment and reconfiguration.

2. Reliable Performance:

- Provides a secure and stable connection that maintains the integrity of the fiber optic pathway.

- Ensures protection against environmental factors that could damage the fiber cables.

3. Flexibility:

- Suitable for both indoor and outdoor installations.

- Can be used in various configurations to extend or repair microduct networks.

4. Cost-Effective:

- Reduces labor costs and installation time compared to other types of connectors.

- Durable and long-lasting, reducing the need for frequent replacements.

Applications

1. Telecommunications:

- Used in the deployment of fiber optic networks for high-speed internet, telephone, and television services.

2. Data Centers:

- Facilitates the routing and protection of fiber optic cables within data centers.

3. Residential and Commercial Buildings:

- Supports fiber-to-the-home (FTTH) and fiber-to-the-building (FTTB) installations.

4. Industrial Sites:

- Utilized in industrial environments where robust and reliable fiber optic connectivity is required.

Installation Considerations

1. Preparation:

- Ensure that the microduct ends are clean and free of debris before connecting.

- Cut the microducts straight to ensure a proper fit and seal.

2. Insertion:

- Insert the microduct ends into the connector until they reach the internal stop.

- For push-fit connectors, ensure a firm push until the microduct is securely seated.

3. Sealing:

- Check that the O-rings or gaskets are properly seated to prevent leaks.

- Ensure the connectors are fully tightened if they have compression fittings.

4. Testing:

- After installation, test the connected microducts to ensure there are no air leaks and that the fiber optic pathway is unobstructed.

5. Maintenance:

- Periodically inspect the connectors for any signs of wear or damage.

- Replace connectors if they become damaged or if the seal is compromised.

Conclusion

HDPE microduct straight optic connectors are essential components in modern fiber optic networks, providing a reliable, easy-to-install solution for joining microducts. Their durability, ease of use, and protective features make them ideal for a wide range of applications, from telecommunications to industrial settings. Proper installation and maintenance of these connectors ensure the longevity and performance of fiber optic systems.