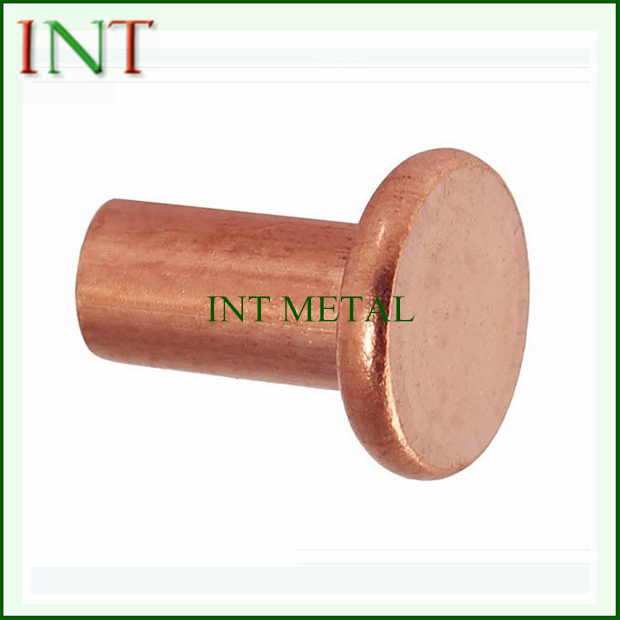

Characteristics and uses of solid copper rivet

2023-11-16

Solid copper rivets are another type of fastener used for joining materials together. Unlike tubular rivets, solid rivets are not hollow and do not have a tubular shape. Instead, they consist of a single, solid shaft with a head on one end. Solid copper rivets are often chosen for their durability, electrical conductivity, and corrosion resistance. Here's an overview of their characteristics and usage:

1. Material: As the name suggests, solid copper rivets are made entirely of copper. Copper is selected for its conductivity, corrosion resistance, and aesthetic appeal.

2. Installation Process: The installation of solid copper rivets typically involves the following steps:

- Hole Preparation: Holes are drilled through the materials to be joined. The size of the hole should match the diameter of the rivet shaft.

- Inserting the Rivet: The solid copper rivet is inserted through the aligned holes in the materials.

- Upsetting or Peening: The end of the rivet protruding from the materials is then deformed, a process known as upsetting or peening. This involves mechanically deforming the end of the rivet to create a second head, securing the materials in place.

3. Applications: Solid copper rivets are used in a variety of applications, including:

- Leatherworking: They are commonly used in leathercraft to create durable connections in belts, bags, and other leather goods.

- Electronics: Due to copper's excellent electrical conductivity, solid copper rivets can be used in electronic applications where a reliable electrical connection is required.

- Construction: In some cases, solid copper rivets may be used in construction and metalworking for their strength and resistance to corrosion.

4. Advantages:

- Strength: Solid copper rivets can provide strong, permanent connections.

- Conductivity: The conductivity of copper makes these rivets suitable for applications where electrical conductivity is important.

- Corrosion Resistance: Copper's corrosion resistance is beneficial in environments where rust or corrosion could be issues.

When choosing between solid copper rivets and other fasteners, factors such as the materials being joined, the load requirements, and the specific properties of copper that are advantageous for the application should be considered.