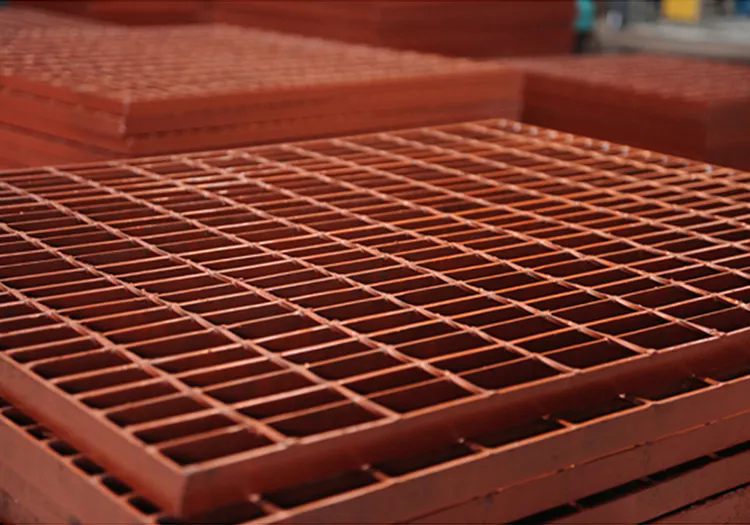

Detailed Overview of Paint-dipped Grating

2024-07-25

Paint-dipped grating refers to a type of metal grating that has been treated with a dip coating process to enhance its durability, corrosion resistance, and appearance. This treatment involves immersing the grating in a liquid paint or coating material and then curing it to create a protective layer. Here's a detailed overview:

Features

1. Coating Process:

- Dip Coating: The grating is submerged in a tank of liquid paint or coating material. After dipping, the excess coating is removed, and the grating is allowed to dry or is cured in an oven.

- Types of Coatings: Various coatings can be used, including powder coating, epoxy coating, and polyurethane coating, each offering different levels of protection and aesthetic qualities.

2. Material:

- Base Material: Typically made from metal materials like steel, aluminum, or stainless steel. The metal provides structural strength and load-bearing capability.

- Coating Material: Paints or coatings are selected based on the desired properties such as corrosion resistance, UV resistance, and color.

3. Durability:

- Corrosion Resistance: The coating provides a protective barrier against moisture, chemicals, and environmental factors, extending the lifespan of the grating.

- Impact Resistance: Enhances the grating’s ability to withstand physical impacts and abrasions.

4. Appearance:

- Aesthetic Finish: Available in various colors and finishes, including matte, gloss, and textured options. This allows for customization based on aesthetic preferences or functional requirements.

- Uniform Coating: Ensures a consistent appearance across the entire surface of the grating.

5. Applications:

- Industrial: Used in industrial settings where corrosion resistance is critical, such as in chemical plants, water treatment facilities, and coastal environments.

- Commercial: Applied in commercial environments like parking structures, pedestrian walkways, and shopping centers for both functional and aesthetic purposes.

- Residential: Suitable for residential applications including decorative grates and walkways.

Benefits

1. Enhanced Corrosion Protection:

- Longer Lifespan: The coating helps protect the metal from rust and corrosion, extending the life of the grating.

- Reduced Maintenance: Lower maintenance requirements due to the protective nature of the coating.

2. Improved Aesthetics:

- Customization: Offers a range of colors and finishes to match design preferences and integrate with surrounding decor.

- Consistency: Provides a uniform and clean appearance.

3. Increased Safety:

- Anti-Slip: Some coatings provide additional slip resistance, improving safety in high-traffic or wet areas.

- Smooth Surface: The coating can help smooth out rough edges, reducing the risk of injury.

4. Environmental Protection:

- Weather Resistance: The coating protects the grating from environmental factors such as UV rays, rain, and extreme temperatures.

- Chemical Resistance: Resistant to chemicals and pollutants, making it suitable for harsh environments.

Considerations

1. Coating Type:

- Selection: Choose the appropriate coating based on environmental conditions, exposure to chemicals, and desired appearance.

- Durability: Different coatings offer varying levels of durability and resistance.

2. Surface Preparation:

- Cleanliness: The metal grating must be properly cleaned and prepared before coating to ensure good adhesion and effectiveness of the coating.

3. Cost:

- Initial Investment: Painted or coated grating can be more expensive than untreated metal grating, but the added protection and longevity may justify the cost.

4. Maintenance:

- Inspection: Regular inspection of the coating for any signs of damage or wear is essential to maintain protection and appearance.

- Repair: Depending on the type of coating, touch-ups or re-coating may be required over time.

5. Environmental Impact:

- Sustainability: Consider the environmental impact of the coating materials and processes. Some coatings are more environmentally friendly than others.

Conclusion

Paint-dipped grating is an effective solution for enhancing the durability, corrosion resistance, and appearance of metal grating. With its ability to provide both functional and aesthetic benefits, it is suitable for a wide range of applications across industrial, commercial, and residential environments. When selecting paint-dipped grating, consider factors such as coating type, environmental conditions, and maintenance requirements to ensure optimal performance and longevity.