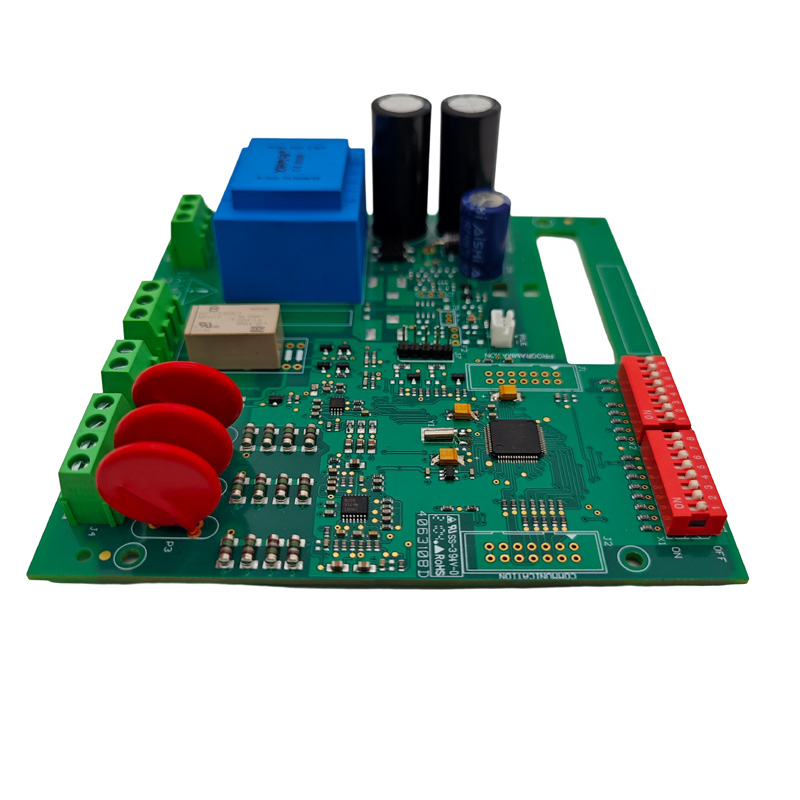

Energy Meter PCBA: The Core of Accurate Energy Monitoring

2025-05-21

With the increasing demand for efficient energy management and smart grid technology, Energy Meter PCBA (Printed Circuit Board Assembly) plays a crucial role in the development of modern energy meters. This key component ensures precise measurement, reliable data transmission, and overall functionality of energy metering devices used in residential, commercial, and industrial applications.

What Is an Energy Meter PCBA?

An Energy Meter PCBA is the fully assembled electronic circuit board that forms the heart of an energy meter. It integrates various components such as microcontrollers, sensors, communication modules, power management ICs, and display drivers to measure, process, and transmit energy consumption data accurately.

Key Components of Energy Meter PCBA

Microcontroller Unit (MCU): Acts as the brain, controlling data processing and communication.

Current and Voltage Sensors: Detect electrical parameters necessary for energy calculation.

Analog-to-Digital Converters (ADC): Convert analog sensor signals into digital data for processing.

Communication Modules: Enable remote data transmission via protocols like Zigbee, Wi-Fi, or PLC.

Memory Chips: Store energy usage data and firmware.

Power Supply Circuit: Ensures stable power to all components.

Importance of Energy Meter PCBA

Accuracy: Precise energy measurement depends heavily on the quality and design of the PCBA.

Reliability: Robust PCBA design ensures long-term operation in various environmental conditions.

Smart Features: Enables functionalities like remote reading, load control, and integration with smart grids.

Customization: PCBA can be tailored to meet specific customer or regulatory requirements.

Applications of Energy Meter PCBA

Residential Metering: Monitoring household electricity consumption with smart metering capabilities.

Commercial and Industrial Metering: Managing energy usage in large facilities for cost control and efficiency.

Renewable Energy Systems: Tracking output from solar panels or wind turbines.

Utility Companies: Facilitating accurate billing and load management.

Manufacturing Considerations

Component Quality: High-grade components ensure durability and accuracy.

Assembly Precision: Automated SMT and DIP processes reduce defects.

Testing and Calibration: Essential to meet industry standards and certification requirements.

Firmware Programming: Tailored software enhances functionality and user experience.

Future Trends

IoT Integration: Energy meter PCBAs will increasingly support IoT connectivity for real-time monitoring and analytics.

Energy Harvesting: Incorporation of self-powered components to enhance energy efficiency.

Miniaturization: Smaller, more compact PCBAs to fit advanced meter designs.

Conclusion

The Energy Meter PCBA is fundamental to the accurate and efficient functioning of energy meters. As energy management becomes more critical in modern society, the demand for high-quality, smart, and reliable PCBAs will continue to grow. Innovations in this field will support smarter grids, better energy conservation, and enhanced user experiences worldwide.