Features and Benefits of Din Rail Terminal Blocks

2024-06-14

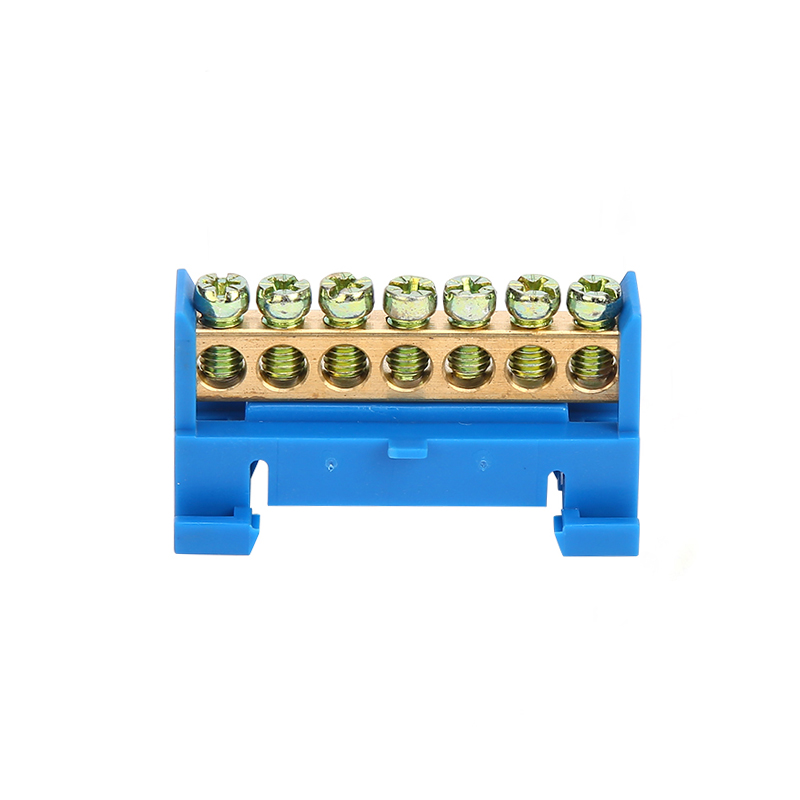

A DIN rail terminal block is an essential component used in electrical and electronic systems for the safe and organized connection of wiring. Here are some key aspects of DIN rail terminal blocks:

Features and Benefits:

1. Standardization: Designed to mount on a standard DIN rail, making them compatible with various enclosures and control panels.

2. Modularity: Allows for easy addition or removal of blocks as the system requirements change.

3. Organization: Provides a neat and tidy wiring solution, which helps in reducing clutter and simplifying maintenance and troubleshooting.

4. Safety: Offers secure and reliable connections, which are critical for ensuring the safety and functionality of electrical systems.

5. Versatility: Available in various types such as screw-in, spring clamp, push-in, and feed-through, catering to different wiring needs and preferences.

6. Accessories: Often come with accessories like end plates, markers, jumpers, and bridges to enhance functionality and organization.

Types:

1. Screw Terminal Blocks: Use screws to secure the wire connections.

2. Spring Clamp Terminal Blocks: Utilize a spring mechanism to hold the wire in place, providing quick and tool-free connections.

3. Push-In Terminal Blocks: Allow wires to be pushed into the terminal block, securing the connection without the need for tools.

4. Feed-Through Terminal Blocks: Designed for straightforward wire-to-wire connections.

5. Ground Terminal Blocks: Specifically designed for grounding purposes, ensuring safe dissipation of electrical faults.

Applications:

- Control Panels: Used in industrial and commercial control panels for organizing and managing wire connections.

- Switchgear: In switchgear applications for connecting and distributing electrical circuits.

- Automation Systems: Vital in automation systems for connecting sensors, actuators, and controllers.

- Building Installations: Commonly used in building wiring installations for distributing electrical power and signals.

- Railway Systems: Utilized in railway signaling and communication systems for reliable and safe connections.

Selection Criteria:

1. Current Rating: Ensure the terminal block can handle the maximum current of the application.

2. Voltage Rating: Check the voltage rating to match the application's requirements.

3. Wire Size Compatibility: Confirm that the terminal block accommodates the range of wire sizes used in the system.

4. Environmental Conditions: Consider factors like temperature, humidity, and exposure to corrosive elements.

5. Certifications: Look for terminal blocks with necessary certifications (e.g., UL, CE) for safety and compliance.

Installation and Maintenance:

- Mounting: Terminal blocks are mounted on DIN rails using a simple snap-in method.

- Wiring: Connections are made according to the type of terminal block, whether it’s through screws, clamps, or push-in mechanisms.

- Labeling: Proper labeling of terminal blocks is crucial for easy identification and troubleshooting.

- Inspection: Regular inspection and maintenance ensure connections remain secure and free from corrosion or damage.

Summary:

DIN rail terminal blocks are vital components for efficient and safe electrical system design. Their modularity, ease of installation, and variety of types make them suitable for a wide range of applications, from industrial automation to building wiring. Selecting the right type of terminal block and maintaining them properly ensures the longevity and reliability of the electrical system.