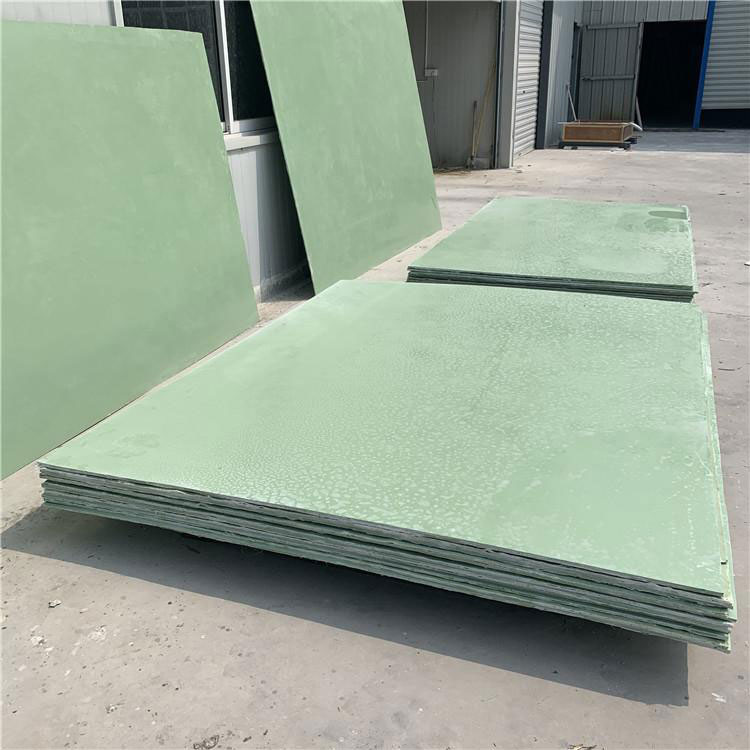

FRP Flat Plate: Lightweight, Durable, and Versatile Composite Material

2025-07-03

FRP (Fiber Reinforced Plastic) flat platesare high-performance composite panels widely used in construction, industrial, and commercial applications due to their excellent strength-to-weight ratio, corrosion resistance, and durability. Made by reinforcing a polymer matrix with glass fibers, FRP flat plates provide a versatile alternative to traditional materials such as metal or wood.

What Is an FRP Flat Plate?

An FRP flat plate is a flat sheet made from fiber-reinforced plastic composites. The fibers (usually glass) embedded in a resin matrix (such as polyester, vinyl ester, or epoxy) give the plate enhanced mechanical properties including tensile strength, stiffness, and resistance to environmental factors. These plates are manufactured in various thicknesses and sizes to suit different applications.

Key Features of FRP Flat Plates

Lightweight:Much lighter than metal or concrete plates of similar size.

High Strength:Strong enough to withstand heavy loads and mechanical stresses.

Corrosion Resistance:Impervious to moisture, chemicals, and UV rays, ideal for harsh environments.

Non-Conductive:Electrical insulation properties make them safe for electrical and electronic applications.

Low Maintenance:Resistant to rot, rust, and degradation, reducing long-term costs.

Customizable:Available in different colors, thicknesses, and surface finishes.

Applications of FRP Flat Plates

Construction:Wall panels, flooring, roofing, and cladding in corrosive environments such as chemical plants.

Electrical Industry:Insulating panels and enclosures.

Marine Industry:Decking, bulkheads, and structural parts resistant to saltwater corrosion.

Transportation:Lightweight panels for vehicle bodies and interiors.

Industrial Equipment:Machine bases, protective barriers, and corrosion-resistant covers.

Architectural Uses:Decorative panels, partitions, and facades.

Advantages of Using FRP Flat Plates

Durability:Long service life even in aggressive environments.

Ease of Installation:Lightweight and easy to cut or shape on-site.

Cost-Effective:Reduced maintenance and replacement expenses.

Safety:Non-toxic, fire-retardant options available.

Versatility:Suitable for both structural and decorative uses.

Considerations When Choosing FRP Flat Plates

Load Requirements:Select thickness and fiber orientation based on mechanical load needs.

Environmental Exposure:Choose resin types optimized for UV, chemical, or moisture resistance.

Surface Finish:Smooth or textured surfaces depending on application aesthetics or slip resistance.

Standards Compliance:Verify compliance with industry standards (e.g., ASTM, ISO).

Conclusion

FRP flat plates combine the best of strength, durability, and lightweight design, making them an ideal choice for many modern industrial and architectural projects. Their resistance to corrosion and ease of handling provide a cost-effective and sustainable alternative to traditional materials, ensuring performance and longevity across a wide range of applications.