Heavy Duty Connector Insert: The Core of Industrial Power Connections

2025-06-20

In modern industrial environments, where high currents, harsh conditions, and reliable connections are the norm, Heavy Duty Connector Inserts play a crucial role. These essential components serve as the internal interface of heavy-duty connectors, ensuring secure, stable, and efficient electrical connections in machinery, automation systems, railways, wind energy, and more. Built to withstand extreme conditions, they are the unsung heroes of many high-performance applications.

What is a Heavy Duty Connector Insert?

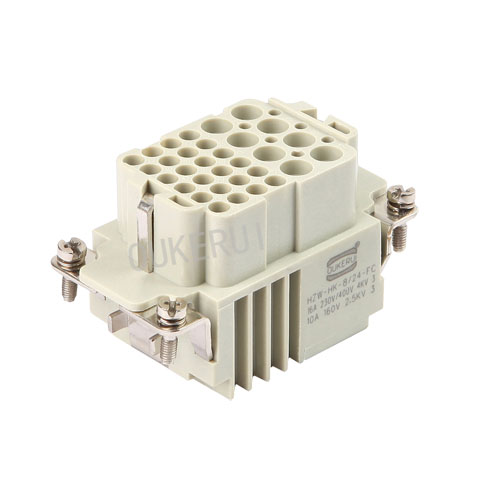

A Heavy Duty Connector Insert is the internal electrical contact module placed inside a rugged connector housing. It is responsible for establishing the actual electrical (and sometimes signal or data) connection between equipment. The insert typically consists of a male (pin) and female (socket) pair, molded from insulating materials like polyamide or thermoset plastics and equipped with metal contacts made of copper alloy or similar conductive materials.

These inserts are commonly used in multi-pole connectors, supporting both power and control circuits in one unit.

Key Features of Heavy Duty Connector Inserts

1. High Voltage and Current Ratings

Connector inserts are designed to handle high power loads — often up to 16A, 32A, or even more — depending on the model. This makes them ideal for industrial machines and heavy equipment.

2. Multiple Contact Options

Inserts come with a variety of contact layouts, such as 6-pin, 10-pin, 24-pin, and even 48-pin configurations, enabling multiple connections in a single interface.

3. Secure Locking and Alignment

Many inserts feature guiding elements and locking mechanisms that ensure precise mating and vibration resistance, even in high-motion or mobile applications.

4. Flame-Retardant and Heat-Resistant

Manufactured from durable, fire-resistant materials, these inserts can operate safely in environments with high temperatures, dust, humidity, or chemical exposure.

5. Modular and Customizable

Heavy duty connector inserts are often modular, allowing users to mix and match power, signal, and data modules according to their specific needs.

Applications of Heavy Duty Connector Inserts

Factory Automation & Robotics

Heavy Machinery & Construction Equipment

Railway and Transportation Systems

Wind and Solar Energy Installations

Control Panels and Power Distribution Units

Shipbuilding and Offshore Platforms

Wherever power or control signals need to be reliably transmitted in rugged conditions, heavy duty connector inserts are a trusted solution.

How to Choose the Right Connector Insert

Number of Contacts: Based on the number of circuits to connect

Current/Voltage Rating: Must match your system’s electrical load

Connection Type: Screw, crimp, or spring terminal

Housing Compatibility: Ensure the insert matches the chosen heavy-duty connector housing

Environmental Requirements: Choose inserts with proper protection ratings (IP65, IP67, etc.)

Conclusion

The Heavy Duty Connector Insert is the heart of secure industrial connections. With superior durability, high performance, and flexible configurations, it provides a critical link between power sources and complex machinery. Whether you're managing an assembly line, operating outdoor equipment, or wiring a wind turbine, choosing the right connector insert ensures maximum reliability, safety, and efficiency — even in the toughest environments.