Here's a breakdown of its key components and usage

2024-03-15

A hammer head toothed T-bolt is a type of fastener used in various applications, particularly in construction, manufacturing, and mechanical engineering. Here's a breakdown of its key components and usage:

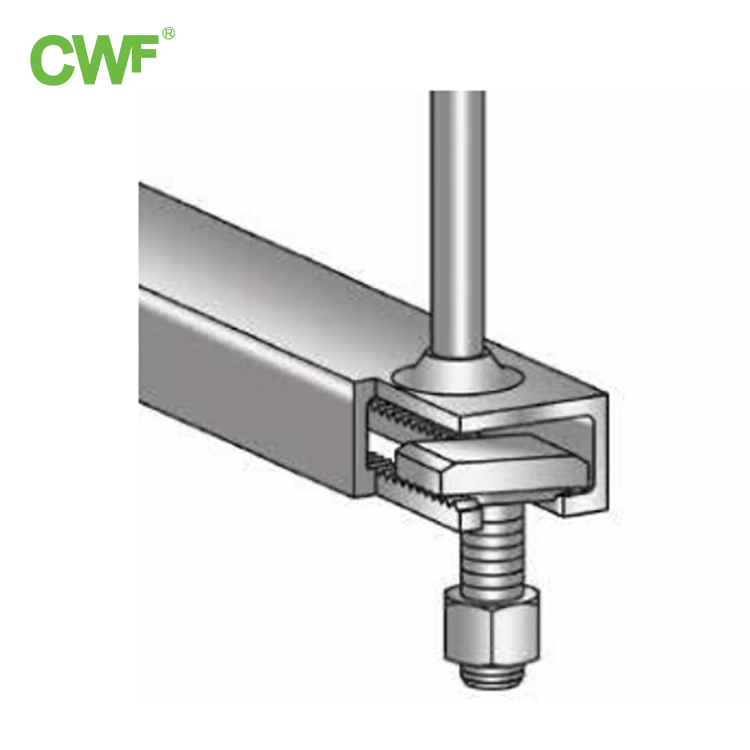

1. T-bolt: The "T-bolt" part of the name refers to the shape of the bolt head. T-bolts have a T-shaped head with a threaded shaft, allowing them to be inserted into T-slot tracks or channels and secured in place with a nut or other fastening element. The T-head design provides stability and prevents rotation within the slot.

2. Hammer Head: The "hammer head" designation indicates that the T-bolt features a flattened head with a larger surface area. This design allows for easy installation and removal using a hammer or mallet. The hammer head provides a convenient means of securing the bolt in place without the need for specialized tools.

3. Toothed: The "toothed" aspect of the T-bolt refers to the presence of serrations or ridges along the underside of the head. These teeth help grip the surface of the T-slot track more securely, preventing the bolt from shifting or loosening under vibration or load. The toothed design enhances the overall stability and reliability of the fastening system.

4. Usage: Hammer head toothed T-bolts are commonly used in applications where a secure and adjustable connection is required, such as in machine frames, workbenches, conveyor systems, and assembly fixtures. They are often used in conjunction with T-slot aluminum extrusions, allowing for modular construction and easy reconfiguration of structures.

5. Material and Size: These T-bolts are typically made from high-strength steel or aluminum alloy to withstand heavy loads and provide long-lasting durability. They come in various sizes and thread pitches to accommodate different T-slot dimensions and application requirements.

Overall, hammer head toothed T-bolts offer a versatile and reliable solution for securing components in T-slot tracks or channels. Their ease of installation, secure grip, and adjustability make them a popular choice for a wide range of industrial and mechanical applications.