High Carbon Steel Wire: Strength and Versatility in Engineering and Manufacturing

2025-03-11

High carbon steel wire is one of the most versatile and durable materials used in engineering and manufacturing. Known for its remarkable strength, durability, and ability to withstand heavy loads and high-stress conditions, high carbon steel wire has found applications across a wide range of industries. In this blog, we will explore what high carbon steel wire is, its properties, applications, and the advantages it offers in various fields.

What is High Carbon Steel Wire?

High carbon steel wire is made from steel that contains a high percentage of carbon, typically between 0.6% to 1.0%. The increased carbon content gives the wire higher tensile strength, hardness, and the ability to resist wear and tear. These properties make it an ideal material for applications that require strength, durability, and resistance to deformation under stress.

The manufacturing process for high carbon steel wire typically involves drawing the steel through a series of dies to reduce its diameter while increasing its length. This process not only improves the wire’s mechanical properties but also ensures uniformity and consistency in the wire’s dimensions.

Key Properties of High Carbon Steel Wire

The unique properties of high carbon steel wire are what make it stand out as a preferred material for many industrial applications. Some of the key properties include:

1. High Tensile Strength

One of the most notable features of high carbon steel wire is its high tensile strength, which refers to the wire’s ability to withstand tension without breaking. This makes it ideal for use in heavy-duty applications where the wire must bear significant loads or resist breaking under stress.

2. Hardness and Durability

The high carbon content makes the wire harder and more resistant to wear and abrasion. This is particularly useful in applications where the wire will be exposed to harsh environments or continuous friction, as it maintains its strength and structure even in challenging conditions.

3. Flexibility

While high carbon steel wire is known for its strength and hardness, it also maintains a certain level of flexibility, making it suitable for various applications that require bending or forming the wire into specific shapes without breaking.

4. Corrosion Resistance

Although high carbon steel is not inherently resistant to corrosion, it can be treated with various coatings such as zinc plating, which enhances its resistance to rust and corrosion. This makes it suitable for outdoor applications or environments with high humidity or exposure to chemicals.

5. Elasticity

High carbon steel wire exhibits elasticity, allowing it to return to its original shape after being stretched or deformed. This property is crucial in applications where the wire is subjected to repeated tension or compression forces.

Applications of High Carbon Steel Wire

High carbon steel wire is used in a wide range of industries due to its strength and versatility. Here are some of the most common applications:

1. Automotive Industry

In the automotive industry, high carbon steel wire is used in the manufacturing of components such as springs, tires, and brake cables. The wire’s high tensile strength and durability make it an excellent choice for automotive applications that require high-performance materials that can withstand constant motion and stress.

2. Construction and Infrastructure

High carbon steel wire is widely used in the construction and infrastructure sectors. It is used in the manufacturing of reinforcement bars (rebar) for concrete, which adds strength to structures like bridges, buildings, and roads. The wire’s high tensile strength ensures that it can support the weight and pressure exerted on these structures.

3. Manufacturing of Springs

High carbon steel wire is commonly used in the production of various types of springs, including compression springs, tension springs, and torsion springs. These springs are used in countless devices, ranging from household appliances to industrial machines, where they store and release energy.

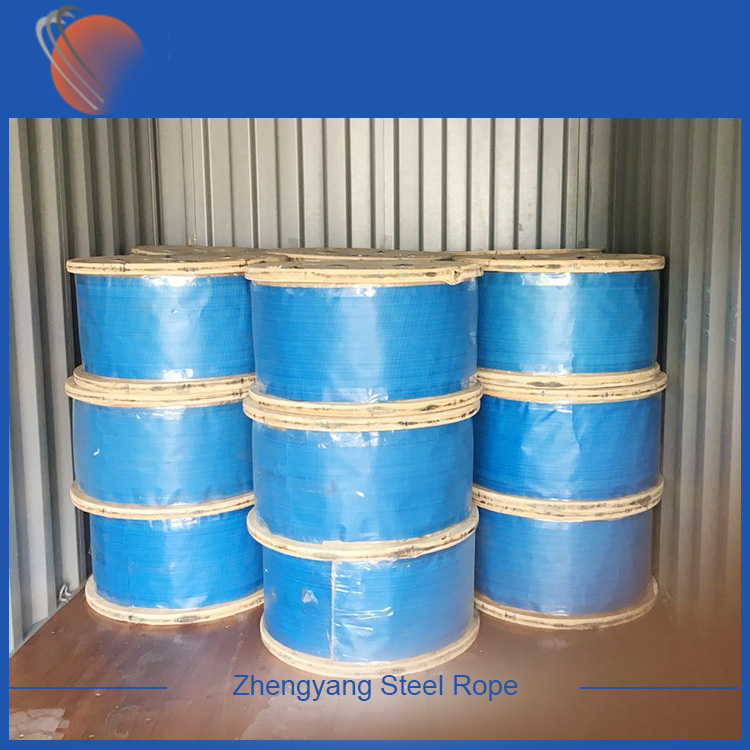

4. Wire Ropes and Cables

The strength of high carbon steel wire makes it an ideal material for producing wire ropes and cables, which are used in a variety of heavy-duty applications, including lifting, hauling, and rigging. These ropes are commonly used in construction, mining, and marine industries, where safety and reliability are paramount.

5. Fencing and Wire Mesh

High carbon steel wire is used in the production of fences, wire mesh, and barriers. These applications require the wire to be strong enough to resist bending, breaking, or deformation while also being flexible enough to form various shapes and structures.

6. Electrical and Electronics Industry

While high carbon steel wire is not typically used for conducting electricity, it is sometimes used in components where strength and mechanical properties are more important than electrical conductivity. For example, it can be used in connectors, springs, and other parts that require both durability and formability.

7. Agricultural Equipment

High carbon steel wire is often used in the production of agricultural tools and equipment, including wire for livestock fencing, trellises, and supports for plants. The wire’s durability ensures that it can withstand the environmental stresses of farming and agriculture.

Advantages of High Carbon Steel Wire

High carbon steel wire offers several advantages that make it a material of choice in many applications:

1. Cost-Effective

Compared to other high-strength materials, high carbon steel is relatively inexpensive to produce, making it an affordable option for many industries. This cost-effectiveness is especially important for large-scale manufacturing processes.

2. Strength-to-Weight Ratio

High carbon steel wire has a favorable strength-to-weight ratio, meaning that it is strong enough to perform well in heavy-duty applications without adding excessive weight. This is important in industries like automotive and aerospace, where weight reduction is crucial.

3. Versatility

Due to its strength, flexibility, and ability to be treated for corrosion resistance, high carbon steel wire can be used in a wide range of applications. Whether it’s in construction, manufacturing, or consumer products, its versatility makes it an essential material in various industries.

4. Customizability

High carbon steel wire can be customized to meet specific needs, such as adjusting the wire’s diameter, hardness, and flexibility. This ability to tailor the wire to suit particular applications makes it even more valuable for specialized industries.

Conclusion

High carbon steel wire is an indispensable material in many industries, offering a combination of strength, durability, flexibility, and cost-effectiveness. Its applications span from automotive manufacturing to construction, agriculture, and beyond. As technology continues to advance and the demands for stronger, more efficient materials increase, high carbon steel wire will remain a key component in shaping the future of manufacturing and engineering.

Whether you are designing an automotive spring or constructing a reinforced concrete building, understanding the benefits and versatility of high carbon steel wire will help you make the best material choice for your project.