Multilayer Boards: The Backbone of Modern Electronics

2025-03-11

In today’s world, electronics are an integral part of our daily lives. From smartphones and computers to medical devices and automotive systems, the complexity of these devices is growing exponentially. At the heart of this complexity lies a key component: the multilayer board.

In this blog, we will delve into the importance of multilayer boards, how they function, the various types available, and their role in driving innovation in the electronics industry.

What is a Multilayer Board?

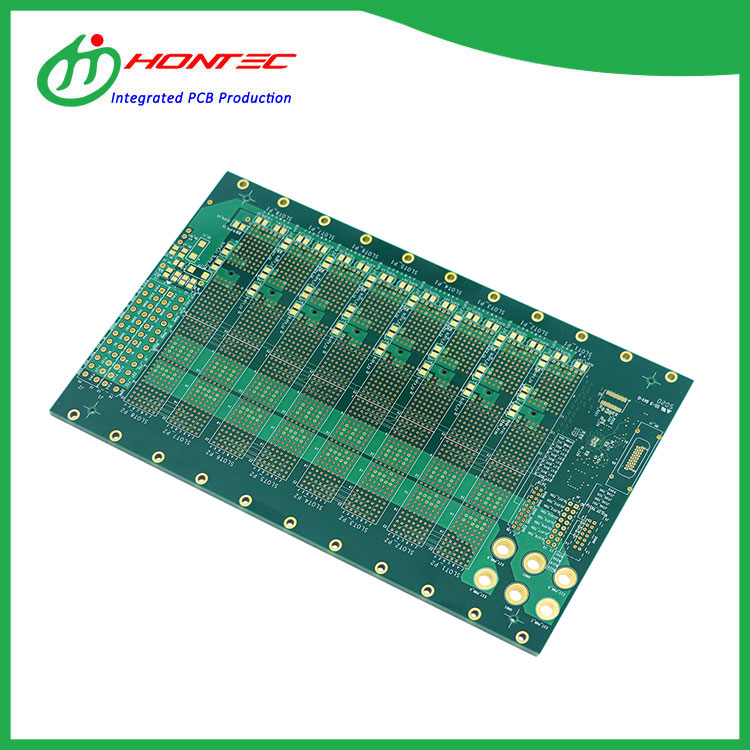

A multilayer board is a printed circuit board (PCB) that consists of multiple layers of conductive and insulating material, stacked together to create a compact and efficient system. Unlike traditional single-layer PCBs, which have just one conductive layer, multilayer boards can have several layers—often ranging from 2 to 12 or more—allowing for more complex and densely packed circuits.

These layers are interconnected through vias, which are small holes that pass through the layers and allow electrical signals to travel between them. The result is a high-density and highly functional board that can support sophisticated electronic designs.

The Importance of Multilayer Boards in Electronics

1. Increased Circuit Density

One of the primary advantages of multilayer boards is their ability to provide a higher circuit density. With multiple layers, designers can pack more components into a smaller space. This is particularly important for devices like smartphones, tablets, and laptops, which require a large number of components in a compact form factor. Multilayer boards allow manufacturers to achieve this compactness without compromising performance.

2. Improved Signal Integrity

As electronic devices become faster and more powerful, signal integrity becomes an increasingly important consideration. With multilayer boards, designers can route signals in a way that minimizes interference and noise. By using dedicated ground and power planes within the layers, multilayer boards ensure that signals remain clear and stable, which is critical for high-speed applications.

3. Enhanced Durability

Multilayer boards are often made from materials that are more durable than traditional single-layer boards. The multilayer structure adds to the board’s resistance to physical stress and temperature fluctuations. This makes them ideal for use in harsh environments, such as automotive, aerospace, and industrial applications.

4. Cost-Effective Manufacturing

Although multilayer boards are more complex to manufacture than single-layer boards, they can be more cost-effective in certain applications. By integrating more components into a single board, manufacturers can reduce the overall size and cost of the final product. Additionally, multilayer boards can reduce the need for multiple interconnects, simplifying the assembly process and lowering production costs in the long run.

5. Improved Performance

With the increased complexity of modern electronics, performance demands are higher than ever. Multilayer boards allow for better power distribution, faster signal transmission, and the ability to support more sophisticated designs. Whether it’s for processing power in a computer or signal transmission in a medical device, multilayer boards provide the performance necessary to meet these needs.

Types of Multilayer Boards

Multilayer boards can vary significantly depending on the number of layers, the materials used, and the intended application. Here are a few common types:

1. Standard Multilayer PCB

This is the most common type of multilayer board, used for general electronic applications. It typically consists of 4-10 layers, with alternating conductive and insulating layers. These boards are often used in consumer electronics, computer systems, and telecommunications devices.

2. High-Frequency Multilayer PCB

High-frequency multilayer PCBs are designed for use in applications that require fast signal transmission, such as in radio frequency (RF) circuits, wireless communication devices, and radar systems. These boards are made from materials that can handle high-frequency signals without signal loss or distortion.

3. Flexible Multilayer PCB

Flexible multilayer boards combine the advantages of flexibility and multilayer technology. These are often used in applications where the board needs to be bent, folded, or twisted, such as in wearable devices, medical equipment, and automotive systems. Flexible PCBs are typically made from materials like polyimide, which allows them to maintain their integrity even in dynamic environments.

4. Rigid-Flex Multilayer PCB

Rigid-flex boards combine the features of rigid and flexible PCBs in one design. These boards are used in applications that require both the stability of a rigid board and the flexibility of a flexible one. Rigid-flex PCBs are commonly used in aerospace, military, and high-performance consumer electronics.

5. High-Density Interconnect (HDI) PCB

HDI boards are a type of multilayer PCB that uses very fine lines and vias to create a densely packed circuit. These boards are typically used in applications where space is limited, such as in smartphones, tablets, and other portable devices. HDI boards can include advanced features like micro-vias and blind/buried vias, which allow for more complex routing of electrical signals.

Applications of Multilayer Boards

Multilayer boards are essential in many industries, and their applications are only growing as technology advances. Some common applications include:

1. Consumer Electronics

In devices such as smartphones, tablets, laptops, and gaming consoles, multilayer boards enable compact designs while maintaining performance and durability. They support the complex circuits required for these devices to function, including high-speed data transfer and multi-tasking capabilities.

2. Automotive Industry

Modern vehicles are increasingly reliant on electronic systems for everything from engine control and safety features to entertainment and navigation systems. Multilayer boards are used in automotive electronics due to their ability to handle high temperatures and vibrations, while also providing the necessary functionality in a small space.

3. Aerospace and Defense

In aerospace and defense applications, multilayer boards are used to build highly reliable and compact electronic systems. These boards are essential in satellite systems, radar technology, avionics, and other high-performance applications where space, weight, and performance are critical factors.

4. Medical Devices

Medical devices such as pacemakers, imaging systems, and diagnostic equipment rely heavily on multilayer PCBs for their compactness and performance. These boards must meet stringent safety and reliability standards, making multilayer designs ideal for handling complex medical electronics.

5. Telecommunications

The telecommunications industry uses multilayer boards to build high-speed communication equipment, including routers, switches, and wireless transmitters. The ability to handle high-frequency signals and minimize interference is crucial in this field, and multilayer PCBs are the solution.

Conclusion

Multilayer boards are at the core of modern electronics, enabling the complex and powerful devices we rely on every day. From smartphones to medical equipment and space exploration, multilayer PCBs offer high-density circuitry, improved signal integrity, and enhanced durability. As technology continues to evolve, the demand for more sophisticated and compact designs will only increase, making multilayer boards a critical component in the future of electronics.

Whether you are designing the next-generation consumer device or a cutting-edge medical instrument, understanding the role and benefits of multilayer boards is essential for ensuring the success and longevity of your project.