Polypropylene Plastic Film: Versatility and Applications in Modern Industries

2025-05-13

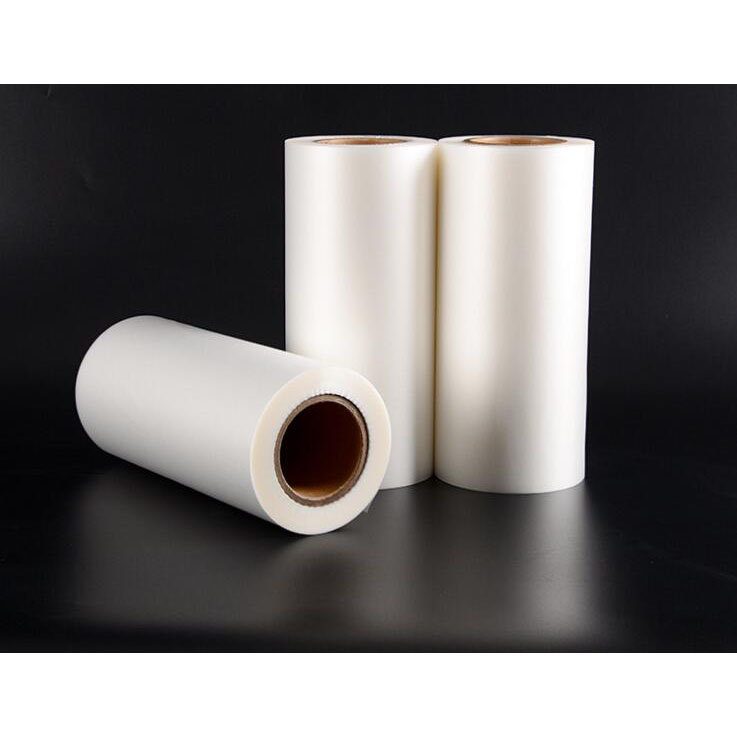

Polypropylene plastic film, often referred to as PP film, is a versatile material widely used in various industries due to its exceptional properties and performance. This transparent, flexible, and durable plastic film is derived from polypropylene (PP), a polymer known for its strength, chemical resistance, and lightweight characteristics. Polypropylene film has gained popularity for both commercial and industrial applications, offering a range of benefits that make it indispensable in the packaging, automotive, textile, and other sectors.

What is Polypropylene Plastic Film?

Polypropylene plastic film is a thin, flexible sheet made from the polymer polypropylene, a thermoplastic material derived from propylene monomers. This plastic film is highly valued for its durability, clarity, resistance to moisture and chemicals, and its ability to withstand various environmental conditions. The film can be produced in different thicknesses and finishes, including matte, glossy, and transparent, depending on the specific requirements of the application.

Polypropylene films are commonly produced through a process called casting or biaxial orientation, which allows the film to be stretched in both directions for increased strength and flexibility. These films can also be combined with other materials to enhance their properties, such as providing heat resistance or improved barrier functions.

Key Properties of Polypropylene Plastic Film

1. Lightweight and Flexible:

Polypropylene plastic film is incredibly lightweight, making it easy to handle, transport, and apply in various products. Its flexibility allows it to conform to different shapes and sizes, making it a popular choice in flexible packaging solutions.

2. Chemical Resistance:

One of the standout features of polypropylene plastic film is its excellent resistance to a wide range of chemicals, oils, and solvents. This makes it ideal for use in packaging food products, pharmaceuticals, and chemicals, where durability and safety are essential.

3. High Temperature Resistance:

Polypropylene has a high melting point compared to many other plastics, making polypropylene films suitable for applications where heat resistance is necessary. It can withstand temperatures ranging from -20°C to 100°C, depending on the specific formulation.

4. Moisture Resistance:

The film's moisture resistance makes it a preferred choice for packaging products that need to remain dry and protected from water or humidity. This quality is especially important for items like electronics, pharmaceuticals, and food.

5. Environmental Resistance:

Polypropylene plastic films are highly resistant to UV rays, which prevents degradation from prolonged exposure to sunlight. This characteristic makes it suitable for outdoor applications, such as agricultural films and outdoor packaging.

6. Clarity and Transparency:

Polypropylene plastic film offers excellent transparency, allowing for clear viewing of packaged goods. This is particularly important for retail products where visibility and product presentation play a significant role in consumer decision-making.

7. Eco-friendly:

Polypropylene is considered a more eco-friendly plastic compared to other materials due to its low environmental impact during production and disposal. It is recyclable and can be reused in various applications, contributing to sustainability efforts.

Applications of Polypropylene Plastic Film

1. Packaging Industry:

The most prominent use of polypropylene plastic film is in the packaging industry, where it serves as a reliable and cost-effective solution for a wide range of products. It is commonly used for wrapping and sealing products like snacks, beverages, pharmaceuticals, and cosmetics. Polypropylene film is also used for making pouches, bags, and blister packs, providing a protective barrier to prevent contamination while maintaining product freshness.

2. Food Packaging:

Due to its moisture resistance and chemical inertness, polypropylene plastic film is widely used in food packaging. It helps preserve the quality and freshness of food by protecting it from air, moisture, and contaminants. It is commonly used for packaging baked goods, meat, dairy, frozen foods, and ready-to-eat meals. Additionally, the transparency of PP film allows consumers to easily view the contents of the packaging.

3. Textile Industry:

In the textile industry, polypropylene film is used for creating protective covers and wrapping materials for clothing and other textiles. It is also used in the manufacturing of non-woven fabrics, which are used for medical gowns, diapers, and cleaning wipes.

4. Agriculture:

Polypropylene films are also used in the agricultural sector, particularly for creating greenhouse covers and mulching films. These films protect crops from harsh weather conditions, retain moisture in the soil, and even help regulate temperature for optimal growth. Agricultural films made from polypropylene offer UV resistance, ensuring their durability under the sun.

5. Printing:

Polypropylene plastic films are used for printing labels, banners, and other promotional materials. The clarity and smooth surface of the film allow high-quality printing, making it suitable for commercial and marketing applications. It is also used for making laminates, providing added durability and protection for printed materials.

6. Medical and Pharmaceutical Applications:

In the medical field, polypropylene plastic film is used for producing medical packaging, such as blister packs for tablets and medical devices. It is also utilized for manufacturing surgical gowns, masks, and disposable covers. Its non-reactive nature ensures that it will not contaminate or react with sensitive medical products.

7. Electrical and Electronics:

Polypropylene films are used as insulation material in various electrical applications due to their excellent dielectric properties. The films are used in capacitors, transformers, and other electronic components to provide insulation and prevent electrical shorts.

8. Construction and Building:

Polypropylene plastic films are employed in the construction industry for applications such as vapor barriers, waterproof membranes, and roofing materials. These films help protect buildings from moisture infiltration and other environmental factors.

Advantages of Polypropylene Plastic Film

1. Cost-effective: Polypropylene plastic film is relatively inexpensive to manufacture compared to other materials, making it a cost-effective choice for many industries.

2. Durable and Long-lasting: With its high resistance to wear, moisture, and chemicals, polypropylene film offers a long service life, reducing the need for frequent replacements.

3. Customizable: Polypropylene films can be tailored to meet specific needs, such as adding coatings for UV protection, printing for branding, or adjusting the thickness for added strength.

4. Recyclable: Polypropylene is one of the most recyclable plastics, contributing to sustainability efforts by minimizing waste and reducing environmental impact.

Conclusion

Polypropylene plastic film is a versatile, durable, and cost-effective material used across various industries, from packaging and food preservation to agriculture and medical applications. Its ability to provide a protective barrier, resist moisture and chemicals, and maintain clarity and flexibility makes it an essential component in the modern world. With increasing focus on sustainability, the recyclability of polypropylene also adds to its appeal as a responsible material for a wide range of applications. Whether you're in need of reliable packaging solutions, agricultural films, or medical-grade materials, polypropylene plastic film offers an ideal solution.